THERMO SET®

Thermo-Setting Technology for Well Integrity , Drilling Efficiency

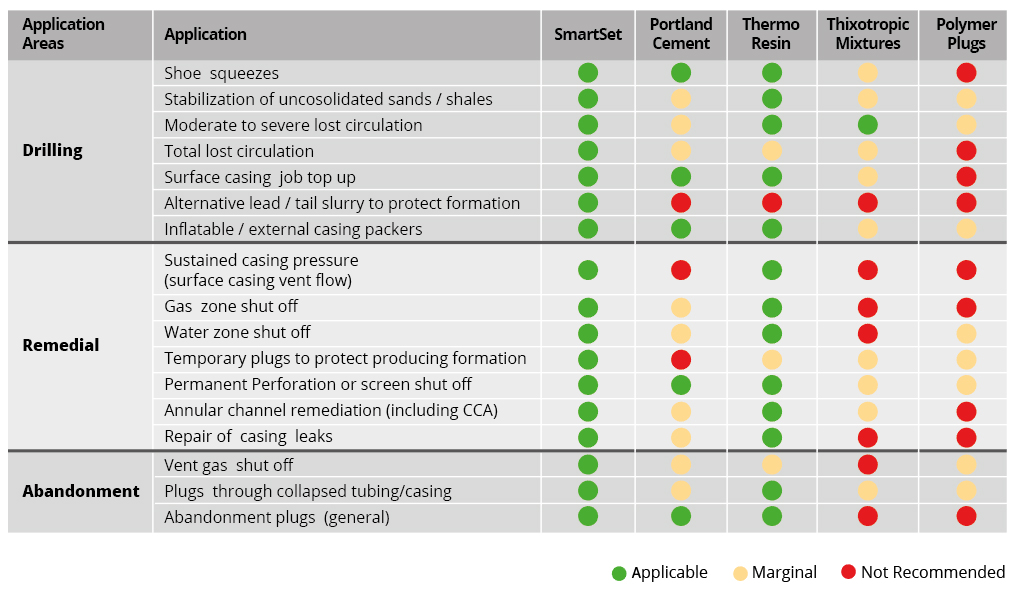

THERMOSET® APPLICATION AREAS

Typically small volumes of ThermoSet® slurry are required to achieve the desired results – often less than one cubic meter for remedial applications. Slurries are mixed at the well site under supervision of a Pluto engineer and pumped downhole using conventional techniques and equipment.

Lost Circulation

Problem

Solution

Result

Problem

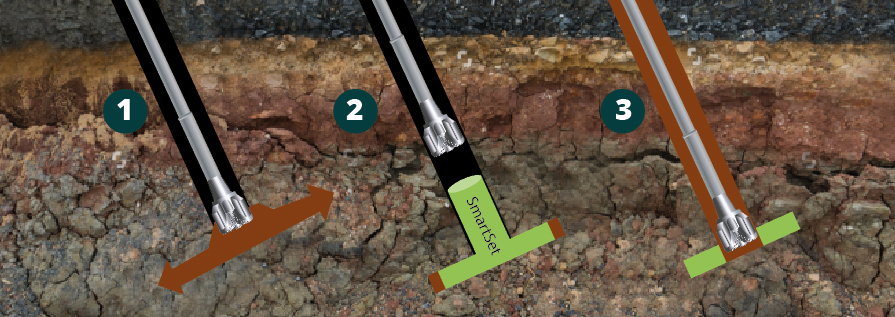

Partial to total fluid losses encountered while drilling.

Solution

- Ascertain temperature @ point of loss +/- 5°C.

- Pickup BHA.

- Spot SmartSet below bit.

- Wait then drill though.

Result

Circulation restored. Continue drilling to total depth.

Benefits

- Ideal for carbonates.

- Pumped through the bit and mud motors – no need to pull BHA.

- Liquid to solid in 120 seconds at set point.

- Ready to drill out in 2 hours after placement.

- Withstands 30% contamination without affect on setting characteristics.

Wellbore Stabilization

Problem

Solution

Result

Problem

Drilling problems from unstable formation.

Solution

- Ascertain temperature @ point of application +/- 5°C.

- Spot SmartSet acrosszone.

- Pick up above plug.

- Wait then drill out

Result

A stable zone and gauge hole.

Benefits

- Pumped through the bit – no need to pull BHA.

- Ready to drill out in 2 hours after placement.

- Easy to drill.

- Withstands 30% contamination without affect on setting.

- Leaves gauge hole over treatment length.

Water Flow Shut Off

Problem

Solution

Result

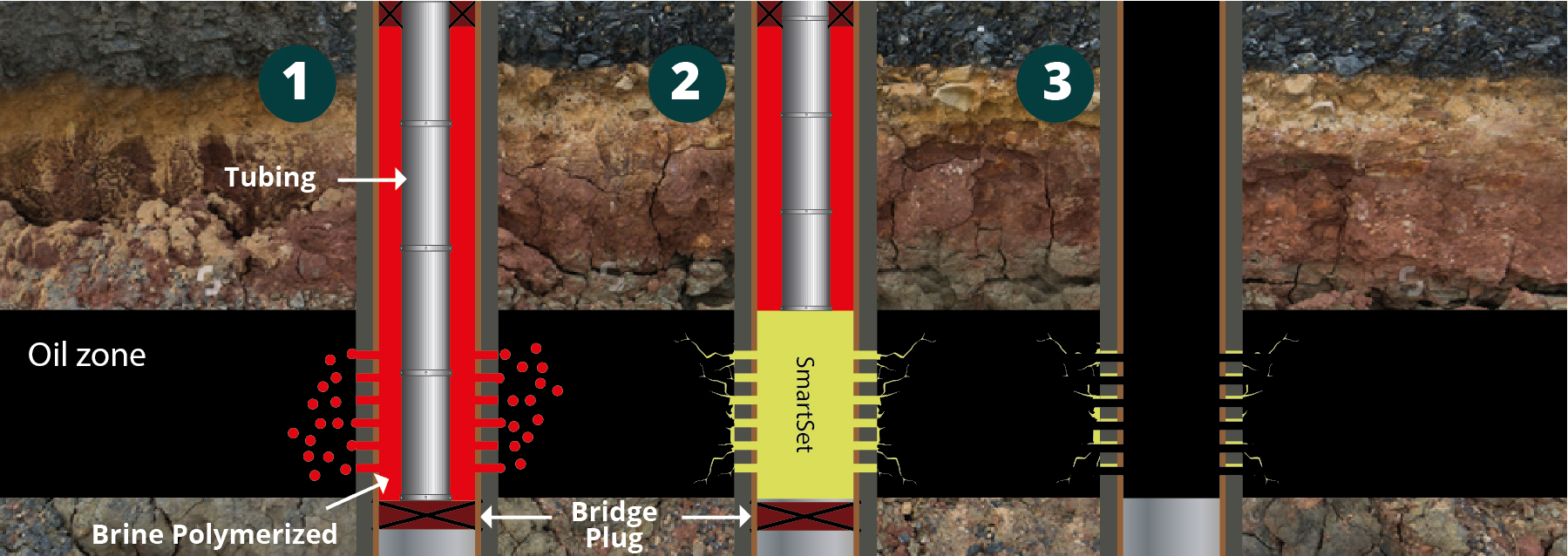

Problem

Water flowing behind casing up through cement to perforations.

Solution

- Identify zone to be isolated and ascertain temperature.

- Set bridge plug below zone.

- Perforate casing.

- Set retainer above zone.

- Sting into retainer, perform leak-off.

- Displace / squeeze SmartSet.

- Drillout / pressure test.

Result

Oil production restored without water.

Benefits

- Can be pumped easily through perforations.

- Easy to drill.

- Set point allows a known calculated squeeze volume.

- Pressure in crease at setpoint indication of job completion.

Temporary Plug to Protect Producing Formation

Problem

Solution

Result

Problem

Heavy brine / polymers damage reservoir during workover.

Solution

- Cover production zone with SmartSet.

- Perform workover.

- Drill out SmartSet.

- Re-perforate and / or acid wash to restore oil production.

Result

Pressure test and resume oil/gas production after drill out.

Benefits

- Can be set with coil tubing (extremely low friction pressure).

- No damage to formation.

- Plug will hold formation pressure.

- Well returned quickly to production.

- Workover rig time minimised.

- No transition / channeling between fluid and set point.

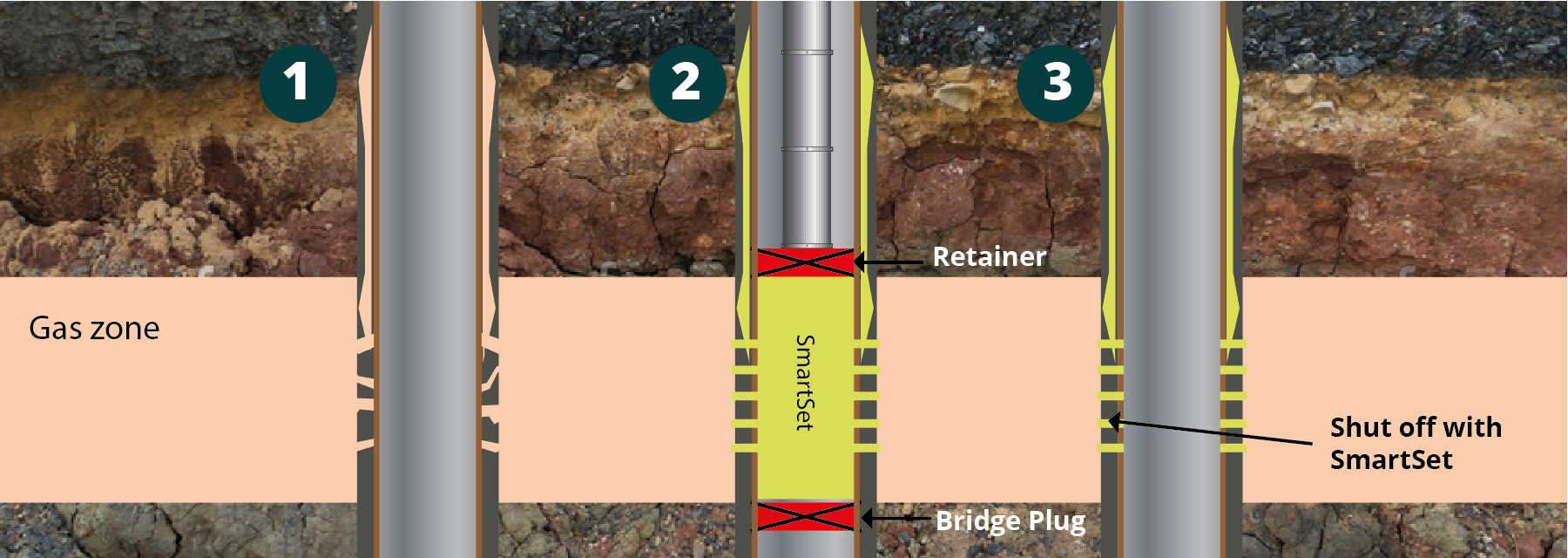

Surface Casing Vent Flow

Problem

Solution

Result

Problem

Gas migration between production and surface casing.

Solution

- Isolate zone to be perforated.

- Perforate at top of gas zone.

- Squeeze SmartSet through perforations and up micro annulus.

Result

- Surface vent gas flow eliminated.

- Drill out and pressure test if desired.

- Perforations shut off with SmartSet.

Benefits

- Low-viscosity, thin slurry with small particle size easy to place in micro annulus.

- Environmentally friendly and non-toxic to ground water.

- Right angle set stops gas.

- Does not dehydrate drilling squeeze displacement.